China Manufacturer Customized SZGH-36Y CNC Lathe High Speed Electric Spindle Milling and Drilling Small Cutter Lathe

Description:

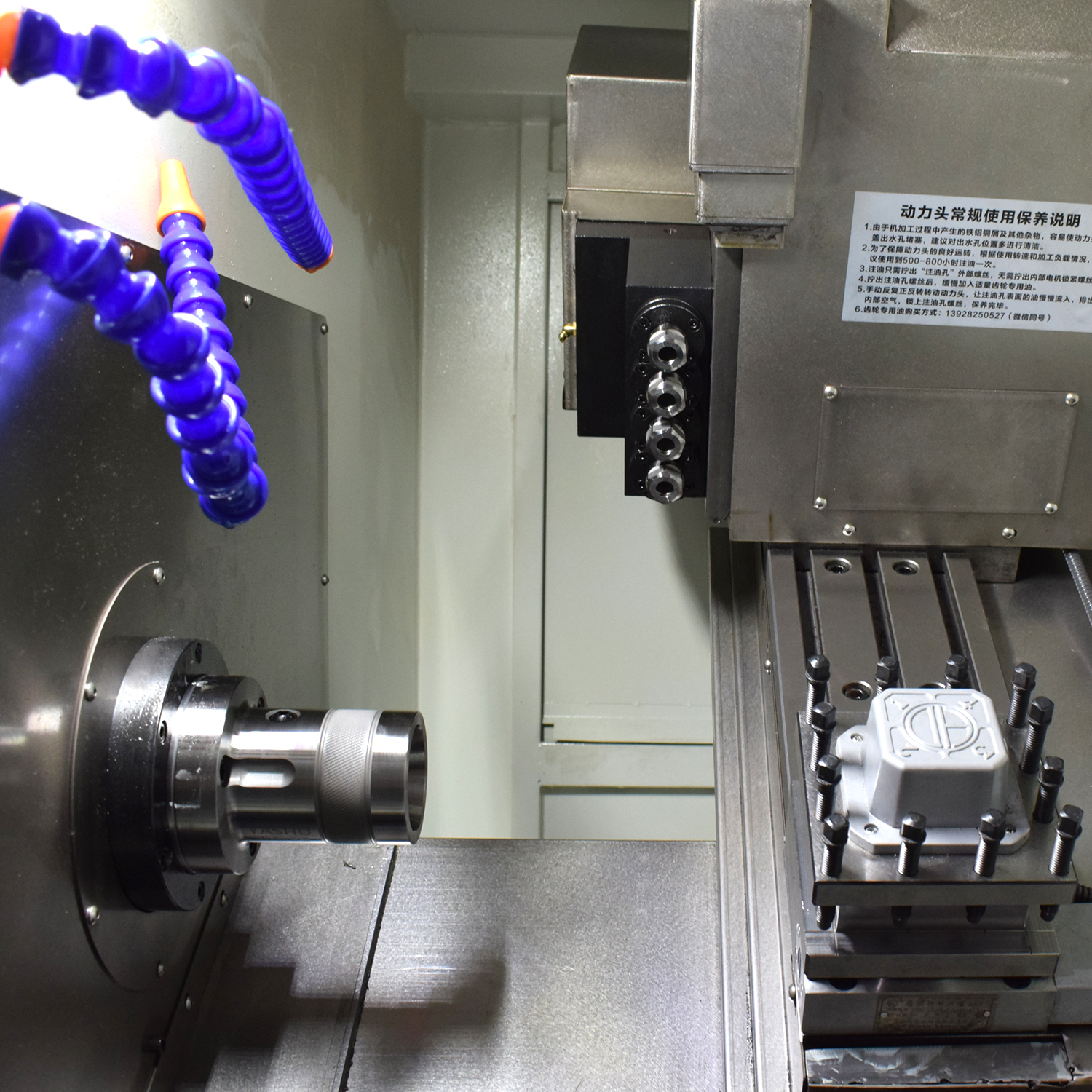

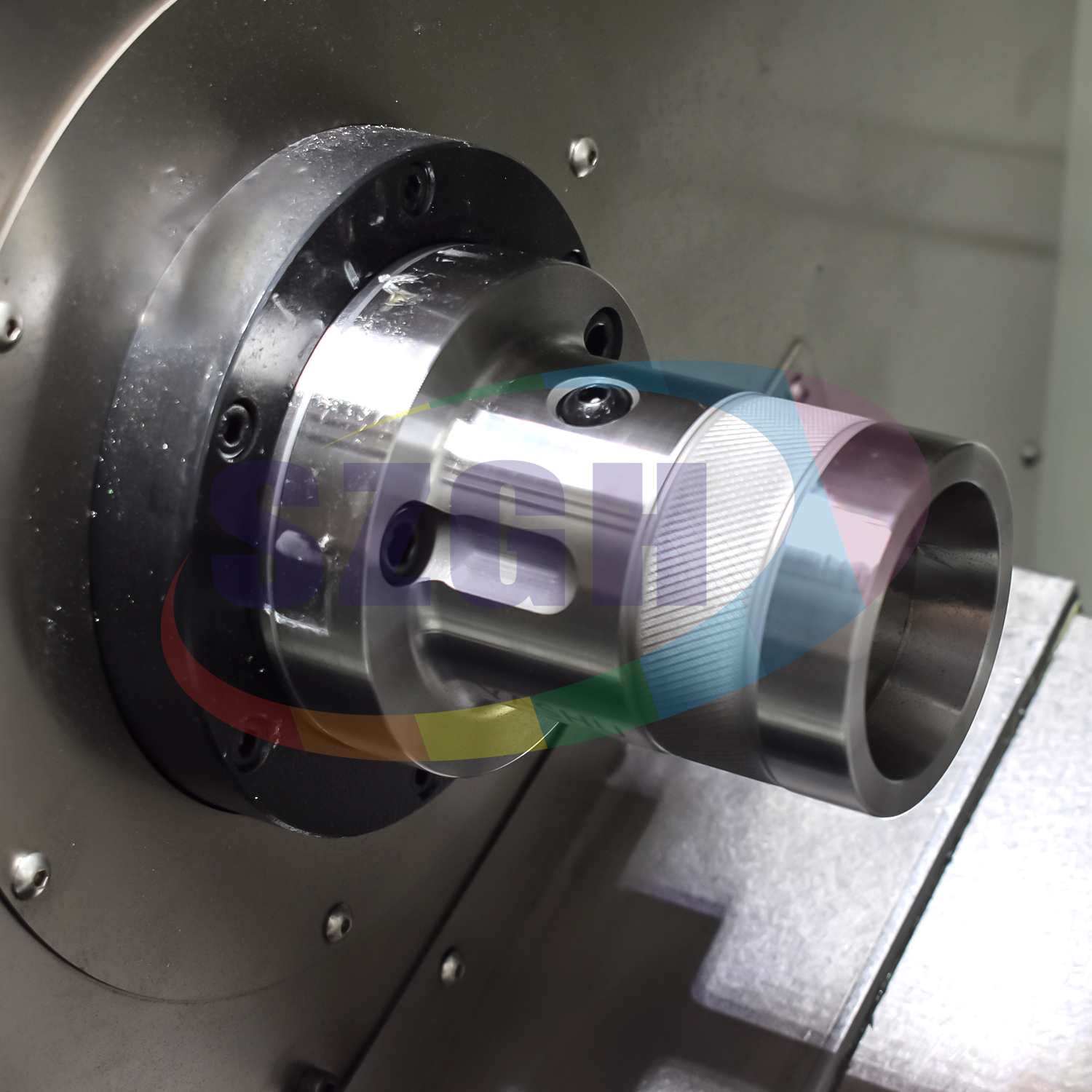

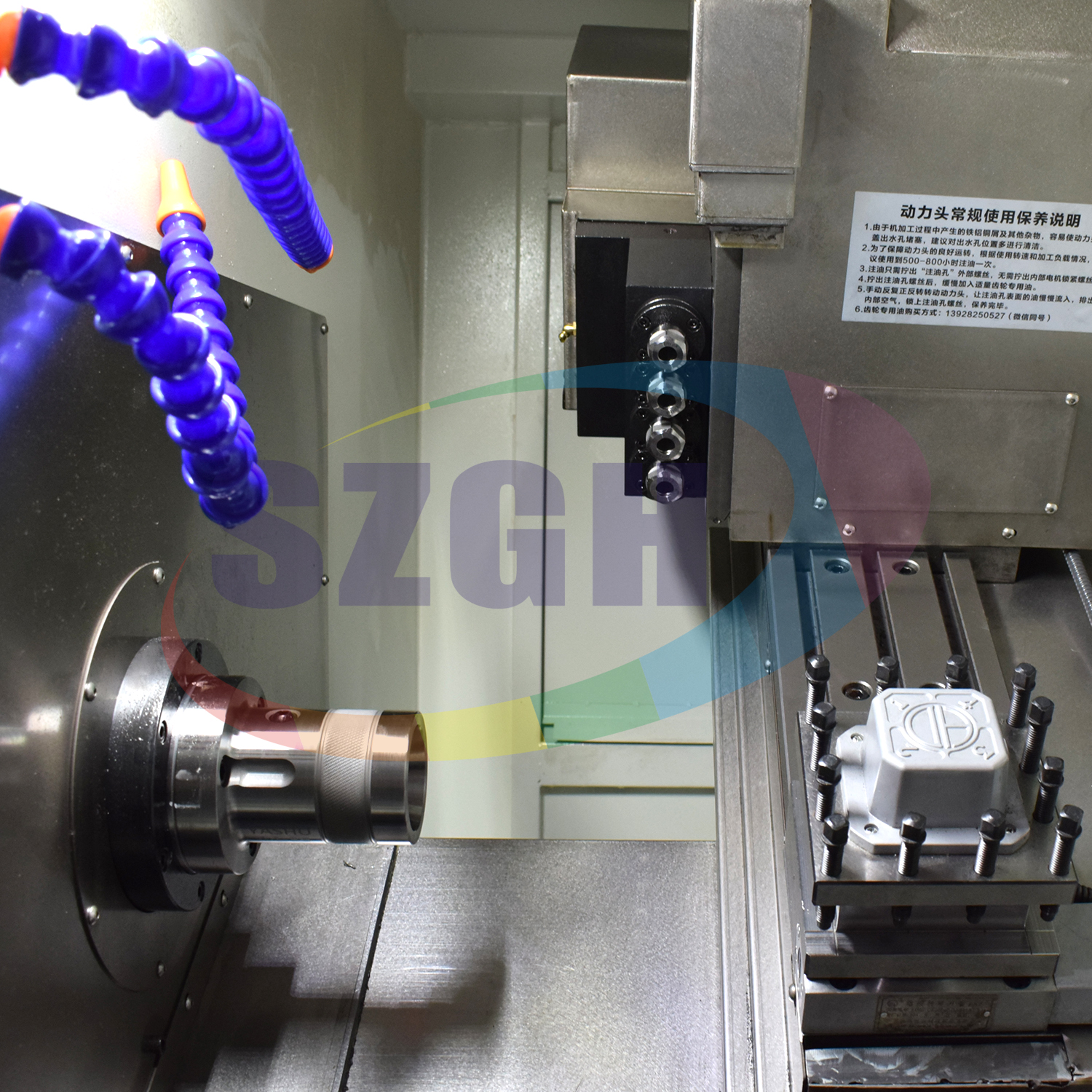

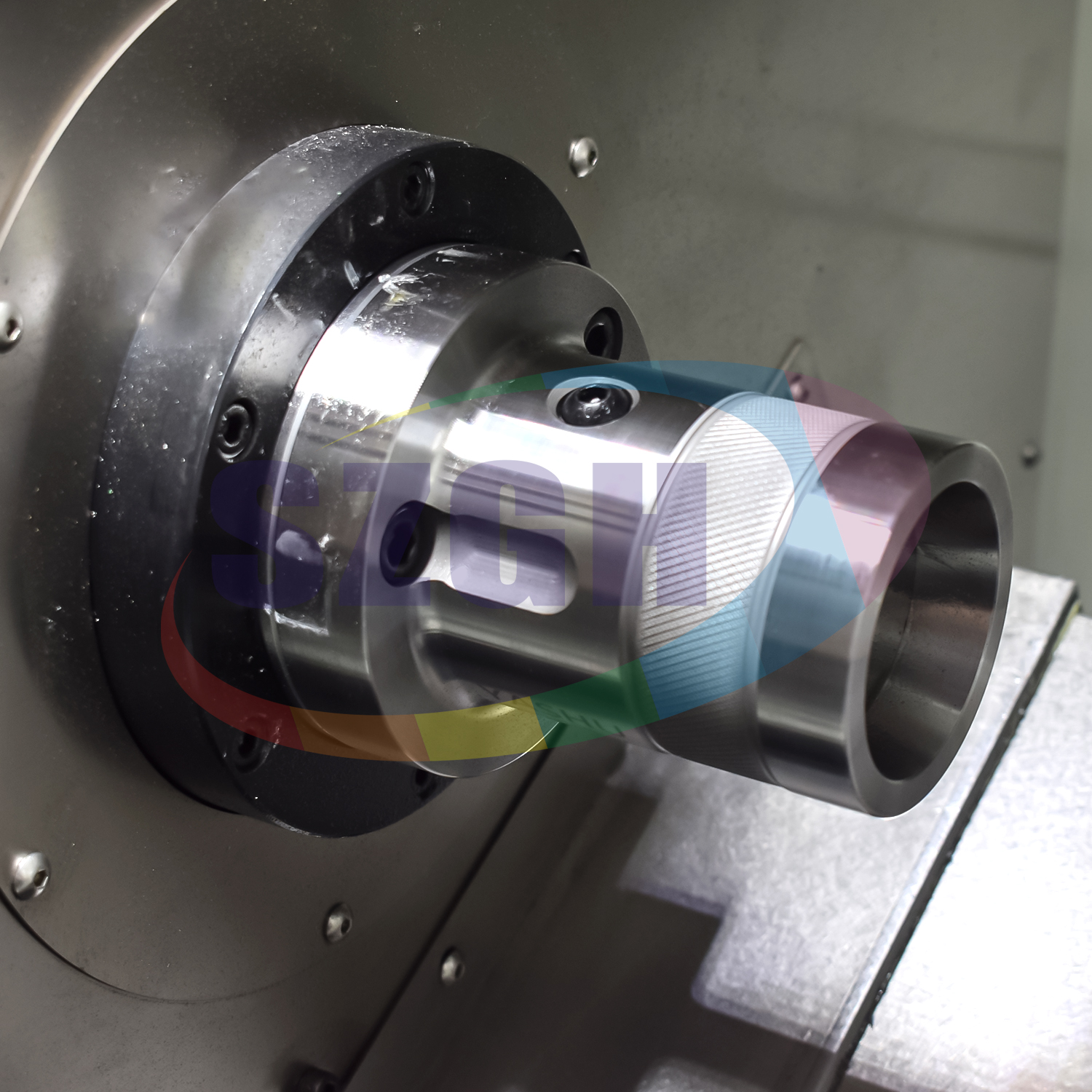

Specializing in the production of CNC lathes, turning and milling composite machining centers and other CNC equipment CNC turning and milling it is suitable for batch production of copper, iron, aluminum and stainless steel bars within 36mm, and automatic feeding batch production of forged parts and other granular materials within 50mm. Adopting multiple patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a single-sided cutting amount within 1.5mm, a precision tolerance within ±0.01mm, and a smoothness of 1.6. It is widely used in ordinary CNC upgrades to improve processing capabilities. By merging the turning and milling processes, repeated clamping errors are reduced, labor and time costs between processes are saved, and it is especially suitable for mass production of economical turning and milling composite parts.

- Model : SZGH-36Y

- OEM : SZGH

- Sample: Yes, sample production provided within 10-15 working days

- Payment : 30% deposit, 70% balance before shipment (T/T or L/C accepted)

- Place of Origin: ShenZhen China

- Supply Ability : 500 units per month

| project | Technical Parameters | maximum value |

| Through hole diameter | φ36mm | φ36mm |

| Accuracy tolerance | ±0.01mm | |

| Processing finish | RA1.6 | |

| Cutting amount per side | 1.5mm | 2.5mm |

| Spindle speed | 3500r/min | 4000r/min |

| Pellets clamping diameter | φ40mm | φ50mm |

| Processing length | 230mm | |

| X-axis travel | 700mm | |

| Z-axis travel | 230mm | |

| Rapid traverse speed | 18m/min | 25m/min |

| Gyrodiameter | φ350mm | |

| Tool holder center height | 40mm | |

| Square knife specifications | □16mm | |

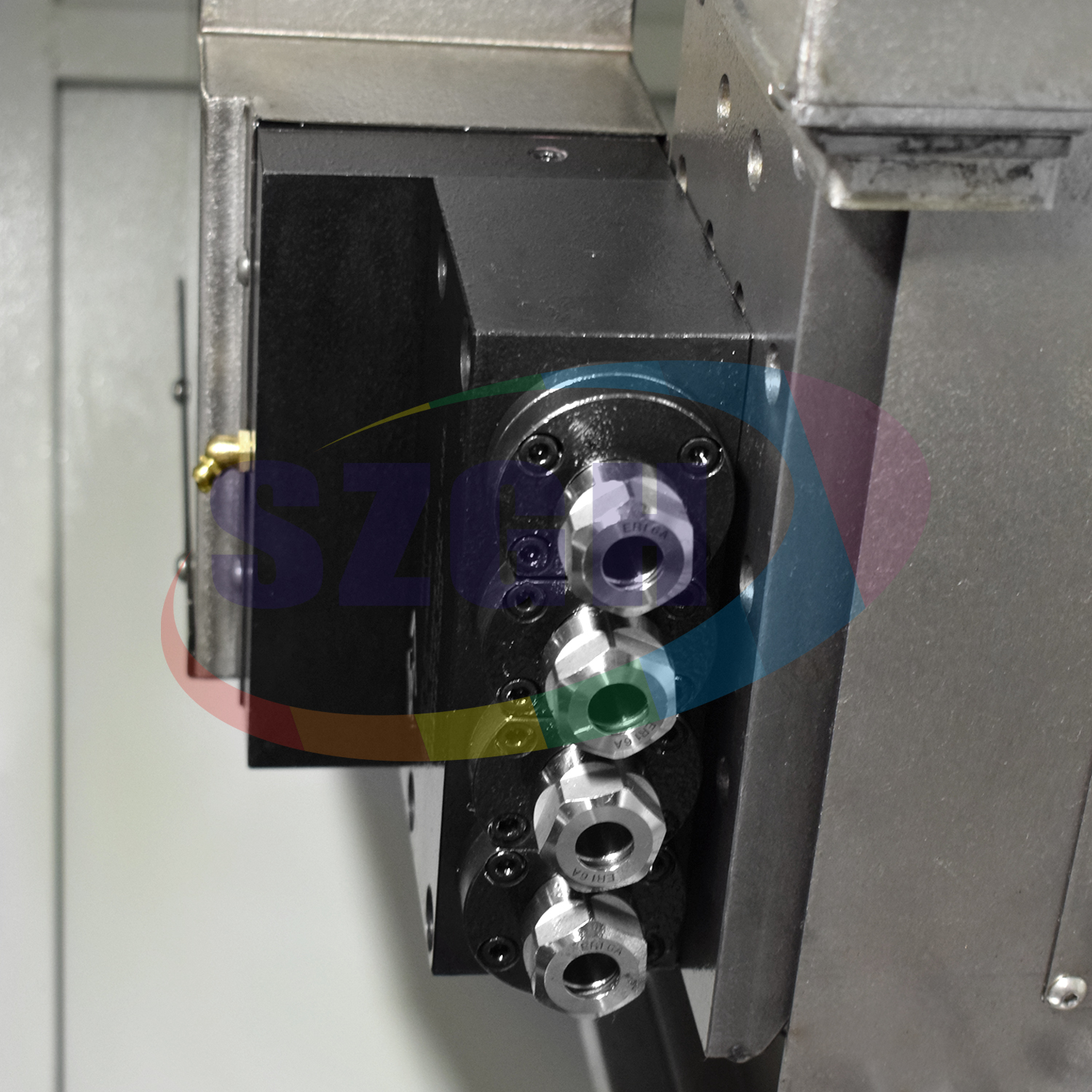

| Y axis mode | Side 3 power head | |

| Y axis travel | 120mm | |

| Y-axis rapid movement speed | 15m/min | 20m/min |

| Power head clamping type | ER25/ER20 spring collet | |

| Maximum drill diameter | 10mm |

| Specification | parameter | brand |

| Lathe bed form | 45° inclined bed | |

| Tool form | row of knives | |

| Guide rail form | 25 linear guide | Taiwan |

| Lead screw | 25 ball grinding precision grade | Taiwan |

| Spindle unit | Homemade high-speed paired bearing unit spindle | Wuxi two-axis (bearing) |

| Spindle nose form | A2-4 | |

| Base form | Heavy-duty anti-deformation patented machine base | Self-researched |

| Height from ground to spindle center | 1080mm | |

Machine size (length*width*height) | 1960*1500*1900mm | |

Machine weight (approximate weight) | 2100kg±5% | |

| Spindle motor | 3kW-4 pole motor | SZGH |

| X/Z axis feed servo | 1.2kW servo | SZGH |

| CNC system | KT830Ti | Open |

| Total machine power | ≈4.5kW | |

| Clamping method |

Please consult sales staff for details